FIDELITY visits … Boulder Amplifiers in Louisville, Colorado

Boulder Photos: Danny Kaey

The world of high-end audio is a strange one. I suppose any hobby at the extreme ends of the spectrum by definition jettison the status quo and aim for the moonshot. Ressence watches is one such company to use the audiophile approved and ever loved mechanical watch industry as a backdrop for a moment. Ressence can genuinely be described as the defacto disruptor of the high-end mechanical watch industry that genuinely took Switzerland by surprise if not outright shock. Jettisoning pretty much all of the existing design choices that everyone else has made, which in reality are nothing more than regurgitated – ad nauseum – reflexive design choices of the last 50-60-ish years, Ressence took the white sheet approach and created what can only be described as a major disruptive design theme with their first release, aptly named Type 1. Visiting the Belgian company’s headquarters or their Swiss manufacturing facility, I can only imagine the enterprising level of ingenuity that runs through their collective veins. Rightfully so, Ressence quickly rose to prominence in the horological world and is de facto a standard for ingenuity in an industry that’s perhaps a bit stale and old school, certainly when compared to the latest tech-y lifestyle consumer goods we are consumed with.

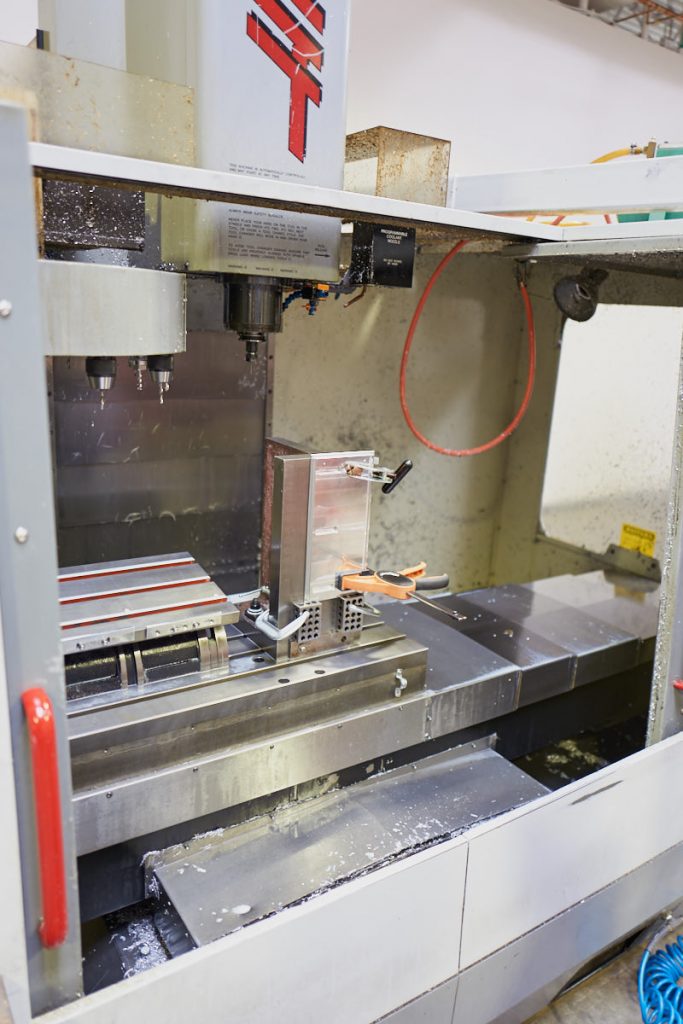

Meanwhile, Louisville, Colorado is home to perhaps one of the few truly highest of high-end audio manufacturers in the US. There are obviously a number of super high-end, super premium manufacturing houses in the US, but only a select few truly push the envelope when it comes to manufacturing standards, which is to say the fit and finish is Hermès like, Ressence like, Rolex like, Bugatti like, well, you get the drift. Naturally, this level of manufacturing competence comes at a price that’s quite commensurate with the offering. Specialty tooling, specialty machinery and the latest state of the art CNC machines cost a bundle. Add environmental regulations, people (the most important element), and budgets quickly start to swell. Economies of scale do the rest. What you get with Boulder is an electronics boutique quite unlike others, where, following my factory visit late August, I was left in awe of their operational excellence and expertise. The factory tour’s front man was Rich Maez, himself a veteran twenty plus year head of sales at Boulder. Affable, a genuine high-end aficionado and consummate salesman, Rich offered up the usual “factory” talk on the shop floor as we walked each of the department head’s sections and operations. Frankly, the tooling itself is a sight to be seen and reminds me of the array of tools at YG and Wilson. All premium, all super expensive – a cutting head for one of the CNC machines that Rich showed me has a replacement cost value of several thousand dollars alone – these tools are not merely part of the process, they are definitive must-have items without which none of the exquisite cutting of aluminum slabs simply wouldn’t be possible.

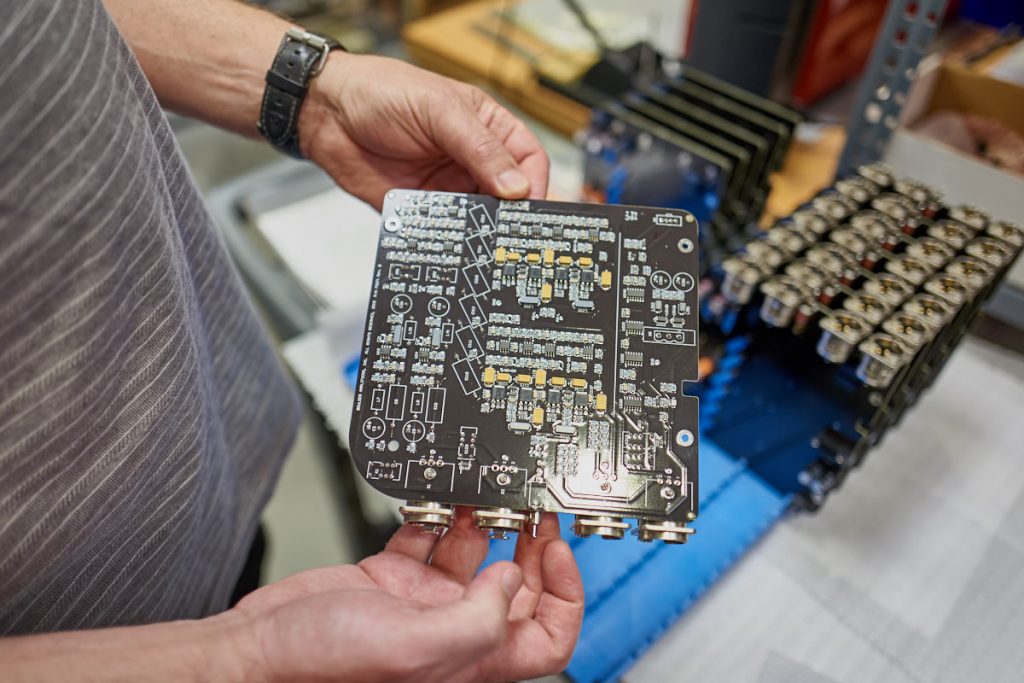

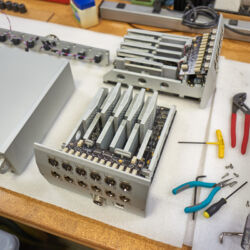

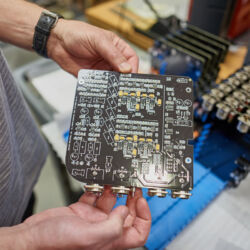

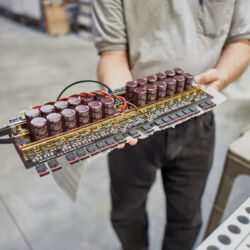

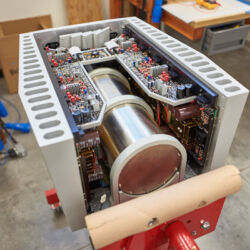

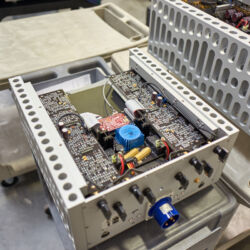

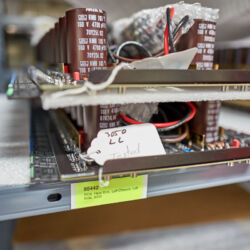

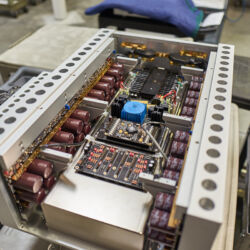

Indeed, everything that you see, touch and feel on a Boulder amplifier is strictly made in house. Perhaps the only other company that offers similar levels of in house manufacturing obsession is YG, who merely a hop and skip down the street in Arvada, build some of the best loudspeakers in the world with the same devilish attention to detail as Boulder. That the two go hand-in-hand is a given and thus its no surprise that many Boulder and YG customers own each other’s product ranges respectively. Back at Boulder, it is striking that each and every component is built fully in house using SMT – surface mount technology – which is the only way to offer the level of electrical qualities and integration Boulder aspires to. Thus, Boulder not only has their own P&P machine (Pick and Place, which is used to mount SMDs), they make their own PCB boards to boot. To say that Boulder is vertically integrated is an understatement, which is to say, Boulder truly builds everything they possibly can in house. Naturally, full control over the build process allows for certain integration to take place which other manufacturers simply cannot. Jeff Nelson, Boulder’s founder and chief electronics engineer, likes it that way. Hearing his excitement and passion come through as he recites the early days of Boulder is infectious to say the least. Steve Huntley, a recent talent acquisition by the Boulder team, handling international sales, was himself awestruck of the who, the what, the why of Boulder. During a conversation with Steve I glanced that he long had admired Boulder and was merely waiting for the right time to join, so to speak. Apparently, timing is key to not only music but many successful moments in life, thusly, the Steve and Rich now share the bulk of global initiatives around the Boulder brand name.

Coming from Boulder’s very first product in 1984, the model 500 amplifier, you’d know with some degree of certainty that Jeff Nelson was onto something special. Mostly going to studios (and still in service today!) and broadcast media where Nelson was a recognized name, it wasn’t until the mid-nineties, 1995, to be precise and the launch of the all new state of the art 2000 series that things really began to shift for Boulder. Designed from the outset to be ne plus ultra components in the form of a stereo amp, mono block version thereof, a preamplifier and DAC, the 2000 series took high-end audio by surprise and frankly by storm. Indeed, it was Sturm und Drang all over again, since sales skyrocketed and Boulder quickly became the “must have” super high-end component system on the market. In 1999 came the 1000 series which today enjoys quite the following and in its latest iteration is well within the percentile of performance even compared to the nighty-mighty 2000 series. But, customers demanded even more. Thus, in 2011, Jeff Nelson launched the ultimate series of components, the 3000 series. Because only more is more, this series simply upended and usurped that which was seemingly possible. A statement product, in much the same way that Bugatti’s Chiron or Wilson Audio’s WAMM is the crown jewel of the brand.

My time at the factory was all too short and I could easily have spent more hours snooping around the various divisions, witnessing operational excellence at the HiFi level. The final straw was partaking in Boulder’s customary coup d’etate, with a visit and listening session at their brand new, fully custom- and purpose-built listening studio. Completely detached – yes, you read that right – from the building’s foundation, the listening studio really is a building within a building. From the outset, the Boulder team wanted to create with as much fanatical detail, a proper listening space that would reveal the most minute differences in their designs. Operated via the aforementioned reference 3000 series, flanked by Focal’s Grand Utopia speaker system, the acoustics and presentation offered up what can only be described as the ultimate experience in HiFi. No matter the track, the sound was simply awesome and monumental in ways that only a handful of systems manage to portray in this fashion. ‘Nuff said.

No doubt this writer’s journey through Boulder has just begun…